Almost by definition, the self-adhesive label is probably the most efficient form of printed packaging. It informs, decorates and promotes a product, cost-effectively and with minimal use of raw materials. For The Label Makers, having a sustainable and efficient approach to manufacture is and always has been good business.

Investment in the latest press technology significantly reduces both setup waste and energy consumption and helps in controlling costs to our customers.

Having been one of the first companies in the UK to embrace 'Zero to Landfill', a British Print Industry initiative, which recycles print waste into heat generation, the installation of solar energy panels now supply the factory with some of its power requirements. LED factory lighting is helping to reduce our requirement for carbon-based energy along with the requirement for all company cars to be hybrid.

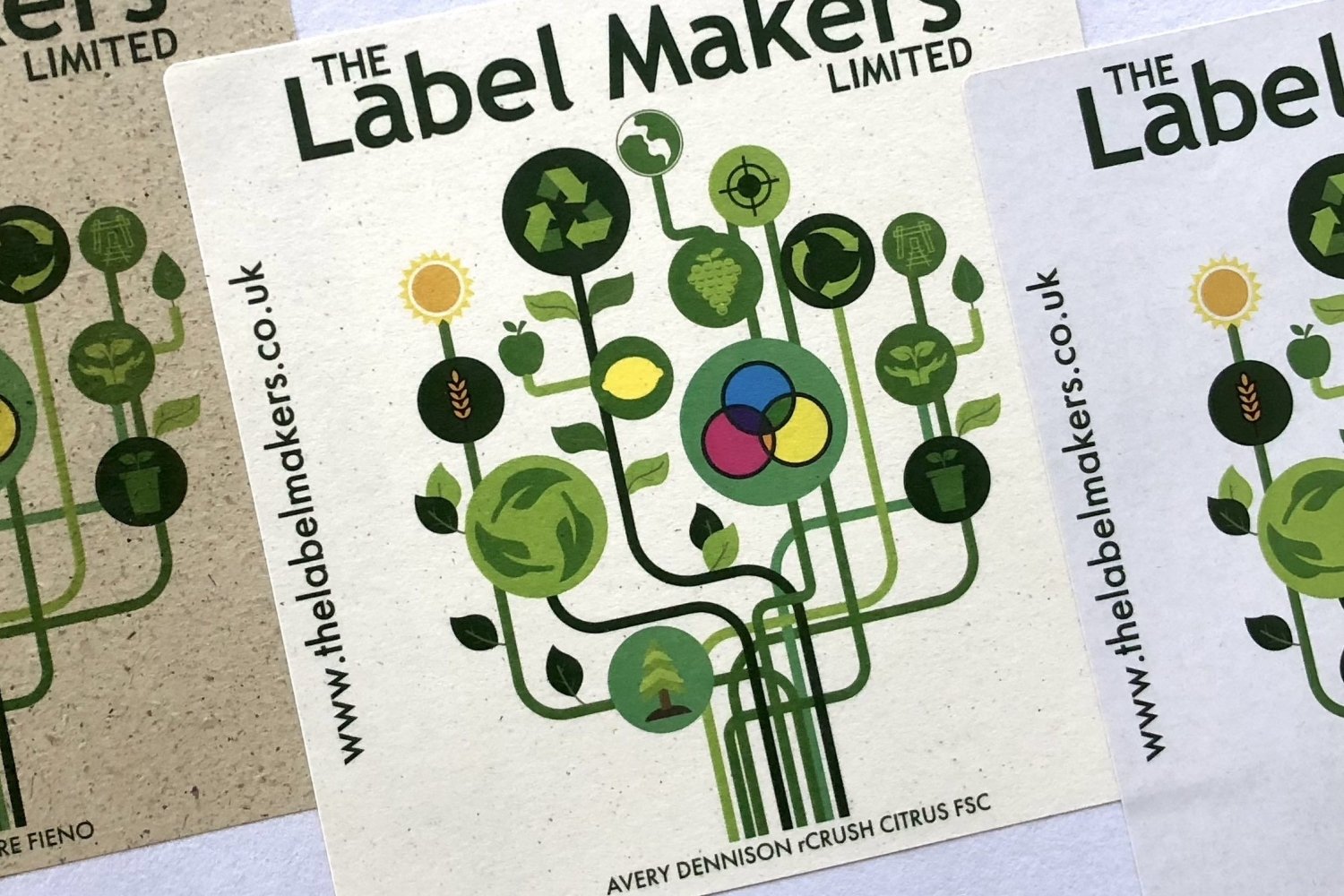

The introduction of eco-friendly labels from new self-adhesive materials derived from agricultural and industrial byproducts is welcomed. Materials include papers made from barley and citrus waste, grass and sugar cane fibre as well as marble powder. Sustainable labels will also feature paper made with 100% recycled content and for the first time, a PE synthetic label material made entirely from 100% post-consumer waste.

In the creation of fully sustainable packaging labels, new adhesive developments have been made to assist with plastics recycling – by ensuring that recyclable bottle labels are easily and cleanly removed, the plastic bottle and containers can then be easily entered into the recycling stream.